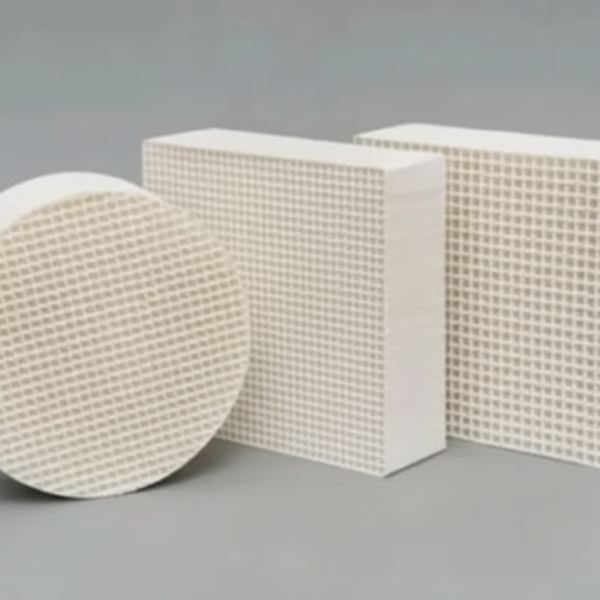

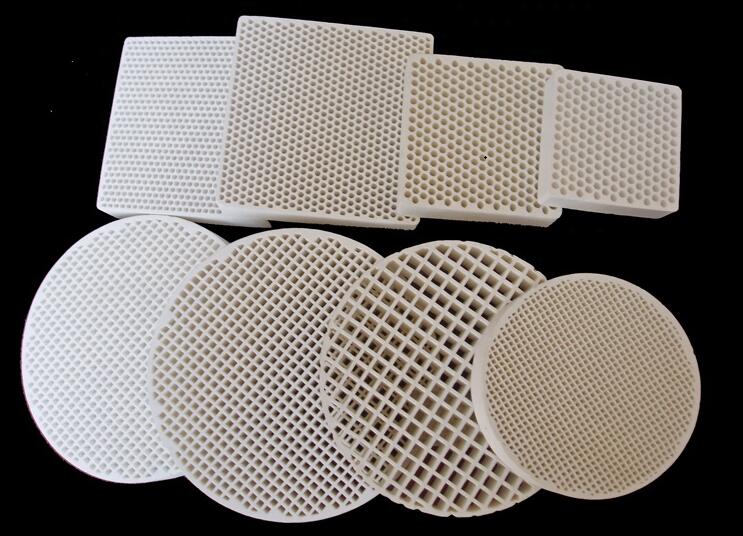

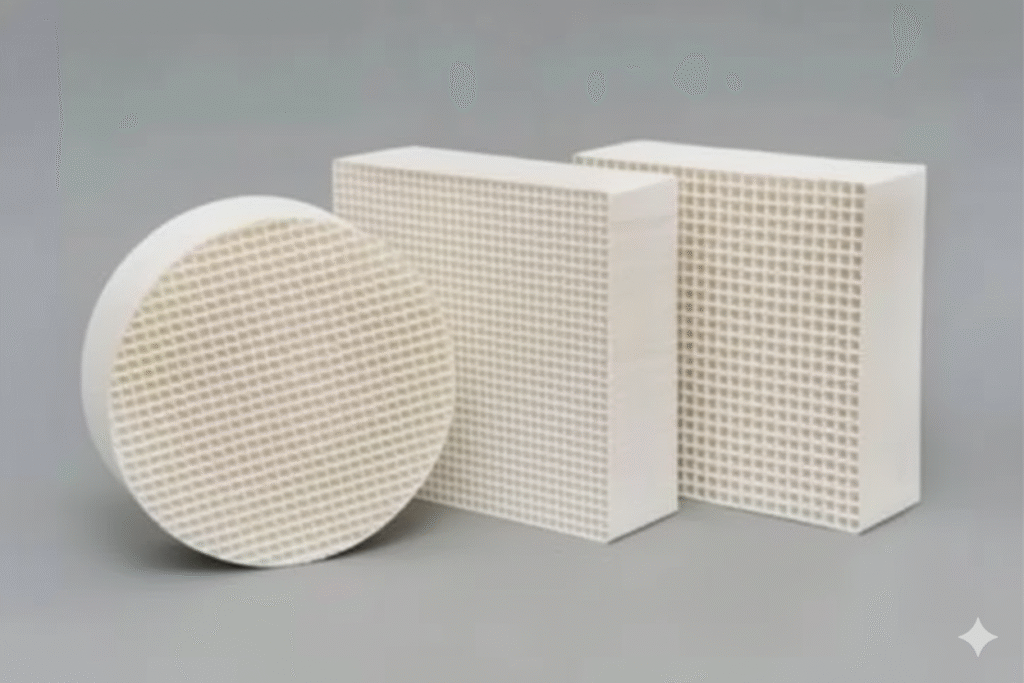

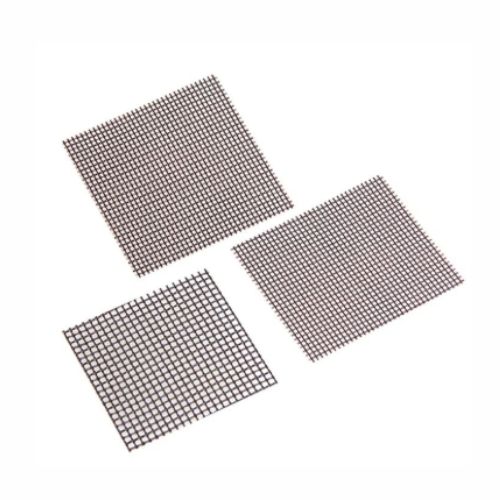

High-performance foundry sleeves are manufactured from refractory materials with precise dimensional accuracy and excellent thermal stability. They are designed to ensure smooth molten metal flow, helping reduce turbulence during pouring.

By minimizing oxidation and heat loss, foundry sleeves contribute to improved casting quality and higher yield in both ferrous and non-ferrous applications.

Key Features

- Manufactured from high-quality refractory materials

- Precise dimensions for accurate fitment

- Excellent thermal stability at high temperatures

- Ensures smooth molten metal flow and reduced turbulence

- Minimizes oxidation and heat loss

- Improves casting quality and yield

- Suitable for ferrous and non-ferrous applications